YAS glass-ceramic used as joining material for SiC/SiC composites

The CEM-WAVE project takes steps in developing new ceramic materials for joining applications. Here are the latest results regarding the joining of ceramic matrix composites operating under extreme environments.

By Carla Malinverni (POLITO – Politecnico di Torino)

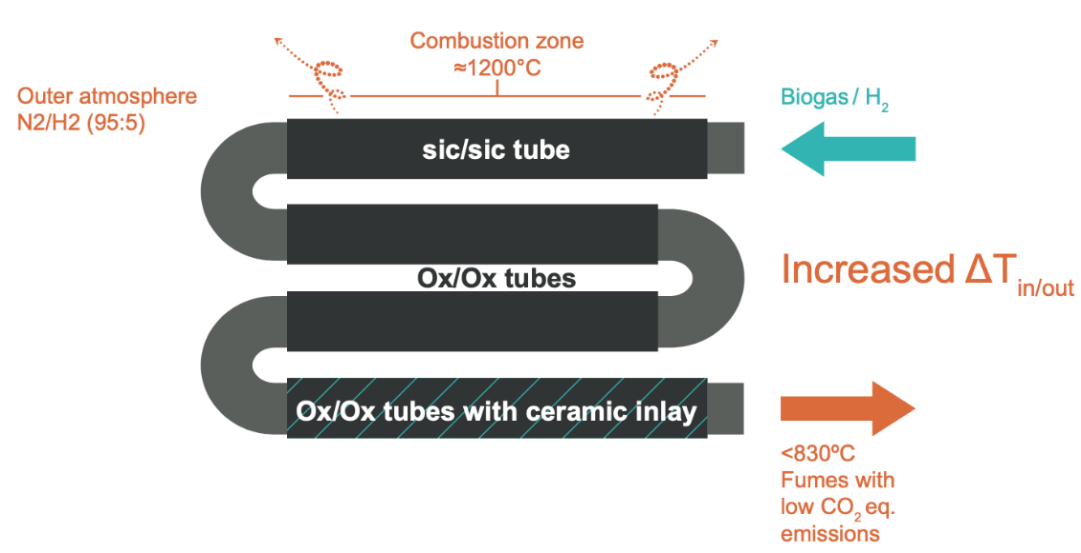

In the framework of the CEM-WAVE Project, non-oxide-based ceramic matrix composites like SiC/SiC were successfully joined using yttrium aluminosilicate (YAS) glass-ceramic. The resulting SiC/SiC joints are intended for use as radiant tube furnace components in energy-intensive industries like the steelmaking sector, which is the target application for the CEM-WAVE Project. The final application of the CEM-WAVE project requires harsh operating conditions characterized by corrosion and combustion environments. Therefore, non-oxide-based ceramic matrix composites, together with glass-ceramics, were selected in this work since their ability to withstand these very high temperatures. In the world of joining, not only glass-ceramic are used as joining materials, but also others such as brazing alloys, MAX phase materials, or for example preceramic polymers. A glass-ceramic system was here chosen thanks to its good oxidation resistance and for its ability to join complex shapes. Moreover, the coefficient of thermal expansion of the glass-ceramics can be tailored according to the substrate to be joined in order to avoid thermal mismatch and glass-ceramics are a good choice for steam operating conditions at high temperature.

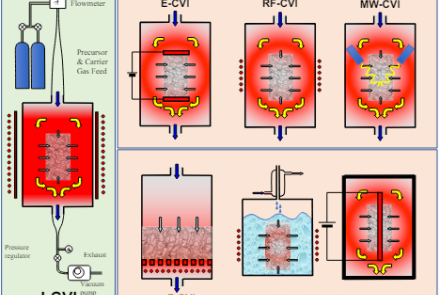

The ceramic matrix composites manufactured in this project will be produced by microwave-assisted chemical vapour infiltration (MW-CVI) process to make high-performance, lightweight materials in order to make their production more sustainable and to enhance the energy efficiency. CMCs are meant to substitute their metallic counterparts like stainless steel and Inconel alloys that are currently used to manufacture these components that are and will no longer be able to resist the required operation condition due to the presence of biogas/H2 mixtures.

Radiant tube as the final application of the CEM-WAVE Project.

In this work, two different SiC/SiC ceramic matrix composites (CMCs) were used as substrates for the joining: the first one was supplied by ATL, UK company, while the other was supplied by BJS, DE company. The YAS glass-ceramic was selected as joining material since its characteristic properties. It has a very high softening point, high electrical resistivity, chemical durability and stability, low thermal conductivity, and a coefficient of thermal expansion that is very close to that of SiC/SiC CMCs, avoiding any mismatch that could lead to induced residual stresses. Two different joining processes were conducted and one of them was optimized and chosen as the most performative one. The joints showed improved adhesion between the glass-ceramic and the non-oxide substrate and mechanical single-lap offset shear testing demonstrated high apparent shear strength, resulting in delamination of the composites.

This study was conducted by the CEM-WAVE partner Politecnico di Torino (POLITO) (Work Package 6 Leader), at the Department of Applied Science and Technology (DISAT) and the J-Tech - Advanced Joining Technology research center at Politecnico di Torino, together with the project partners Archer Technicoat Ltd (ATL) which supplied the SiC/SiC composites, and Fraunhofer Institute for Silicate Research ISC (FHF) that supplied the YAS glass powders. The morphological characterizations of the samples obtained using field-emission scanning electron microscope were carried out at the AGH University of Krakow thanks to funding from the European Union’s Horizon 2020 research and innovation program under grant agreement No. 823717 – ESTEEM3 (CeramECS and GlaMater).

The results have been published open access in the Journal of the European Ceramic Society, at the link https://doi.org/10.1016/j.jeurceramsoc.2023.12.095

Scientific paper published on the Journal of the European Ceramic Society.