Decoding the Fundamentals of the CEM-WAVE Project

Professor Jon Binner (Professor of Ceramic Science and Engineering – school of Metallurgy and Materials) at the University of Birmingham, explains in this insightful interview the fundamentals of the CEM WAVE Project to better understand it.

Ceramic Matrix Composites are not entirely new materials, they've been around for about 30 years now but, they are really developing fast these days and there's a tremendous interest globally in using them, and the question is why.

Why are CMCs valuable materials worthy of research?

Ceramics have been around for a very long time. 30,000 years ago, early Humanity learned how to make basic pottery, and that's come a long way now we are working very much on Advanced Ceramic Materials in the form of Composites and we know that in general, if you look around all that we are doing, whether it's Aerospace industry or other types of Industry, manufacturing industry in general, we are moving towards higher temperatures, higher pressures and the use of more critically dependent materials. Ceramic Matrix Composites offer a tremendous advantage here.

They are materials which are very high-temperature capabilities in general, higher temperature than most metals. They offer very good toughness’s compared to the straightforward uncomposed the advanced ceramic material. These have toughness values of 2 three four mega Pascal root meters whereas our Composites can be 15 20 even 25. Fibre-reinforced Composites such as we're working in CEM-WAVE have toughness’s of around 25 megapascal root meters. So, we have really good temperature capability, we have very good toughness these days, and also, we have materials that basically are fairly immune to the conditions around them and they're low in density. So, the applications are really developing fast now, as fast as we can develop the materials.

What kind of composites do exist?

There are two basic types of composites; There's what's known as ‘’the weak interface’’, and ‘’the weak matrix’’. The weak interface is the type that everybody always wants. The Composites are relatively strong, they get their enhanced toughness by having a weak interface between the fibre and the Matrix. This is how silicon carbide matrices work. Unfortunately, people in the past (this is the 1990s) tried this with oxide and failed to deliver it, so they developed an alternative approach which is the Matrix so, you make a matrix quite literally that's still quite porous. That works, it gives you the toughness but it doesn't give you the strength.

What is the difference between heating silicon carbide-based composites and oxide-based composites in terms of equipment adaptation?

Silicon carbide absorbs microwave energy oxides do not. Therefore, we’ve had to adapt the system so we can cope with heating materials that intrinsically do not want to absorb microwaves and do not want to get hot. We’ve solved this problem by moving to a variable frequency magnetron so that gives us and a greater ability to tune the system to suit the materials.

What types of testing systems are utilized for CMCs, and which one is employed in the CEM WAVE project?

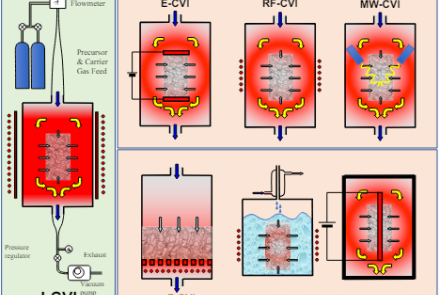

We have two different systems here; we have a microwave-based system and we have a radio frequency-based system. The microwave-based system was originally developed for silicon carbide-based composites. It's now being adapted, as part of this program, to the oxide-based system but we made sure it could still be used for the silicon carbide-based system. We don't have any work on that going on at the moment so the microwave-based system is only used for this CEM-WAVE project, nothing else.

The other system approach we have is radio frequency. Now that is designed for heating carbon fibre-based composites and that is a separate piece of equipment and that is still used as part of another research program but that's quite different it's designed for ultra-high temperature Ceramic Matrix Composites, so these are composites which can take 3,000 de Centigrade. The two pieces of equipment do share one or two critical items such as the gas delivery system, and that was completely deliberate when we established the original system. The space where the equipment sits is relatively small.

Can you tell us more about the work you are doing at UoB and the CMCs applications?

The work we're doing here at the University of Birmingham is focused very much on developing oxide based Ceramic Matrix Composites technology (ox-ox CMC as we call it). These are materials which are in general aimed at relatively modest temperatures for advanced ceramic materials, so we're looking for maximum temperature applications 1,000 to 1200° Centigrade. They're not really intended for any higher temperatures than this. However, there are a lot of applications not only the ones that we are researching here in CEM-WAVE, which is hopefully to help industry, but also, they have applications in things like jet engines, where they can take some of the intermediate temperatures rather than the high temperatures.

We have people wanting to use these applications range from the sorts of things we're looking at in CEM-WAVE, which is trying to help our Industries which can tend to be a little profligate with energy and to help them save energy because they can use these materials that are lighter in weight and then also still able to give the temperature performance and they have the toughness which was so lacking in conventional Advanced Ceramics. But, not only is the industrial, companies but also things like the Aerospace industry are starting to use these materials. So, we're seeing ceramic Matrix Composites actually in jet engines right now that we can fly on at the moment, they're only used in parts that do not rotate within the engine but at some point, in the future they may start to be used in actual rotating Parts within the jet engine but as far as I'm aware that hasn't happened yet when it does it's likely to happen in military engines first and then it will move on into civilian engines. That's still a little way into the future but, probably only another 10 years or some like that and we will see this transformation.

Let's explore what the future holds for CMCs and its applications.