Advancing Sustainable Materials for the heavy industry

Europe is seeking innovative solutions to tackle climate change challenges. To meet this need, the CEM-WAVE project has concentrated its research on advanced materials that can endure the harsh conditions of heavy industry production processes. The goal is to optimize the transition to renewable energy sources while ensuring high efficiency and performance.

At the forefront of this initiative are Ceramic Matrix Composites (CMCs), known for their exceptional toughness, low density, and high thermal resistance. Despite their advantages, the high cost of raw materials and processing has limited their use to high-end applications.

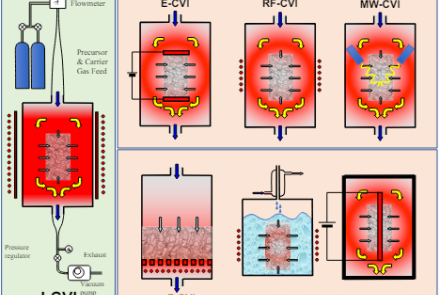

CEM-WAVE aims to revolutionize CMC production with Microwave-assisted Chemical Vapour Infiltration (MW-CVI) technologies, making CMCs more accessible for energy-intensive sectors like steelmaking. The project focuses on developing a CMC tubular prototype for radiant tube furnaces, which will be tested in environments with increasing hydrogen content.

Some of the key achievements up-to-date include:

- Fraunhofer (FHF): Developed tubular preforms using SiC fibers, demonstrating a reproducible and cost-efficient process.

- UNIPI and UoB: Enhanced MW-CVI systems for SiC and oxide CMCs, achieving high-purity alumina matrix deposition.

- Fricke und Mallah (FM): Developed a powerful 2 kW x 3 MW solid-state microwave system for precise frequency tuning.

- IPCF-CNR: Created numerical models for optimizing MW-CVI processes.

- ENEA: Researched the thermomechanical characteristics of CMCs and tested environmental barrier coatings (EBCs).

The 48 month project is in its final phase, with preparations for the final conference in September that will be held in Pisa. Further details on the project's current status can be read through the Innovation news article blog or watching the last dissemination video published.

Upcoming challenges include validating the CMC tube prototype in a pilot-scale furnace developed by Arcelor Mittal (AMIII), and further enhancing the CMC tubes' performance under hydrogen-based atmospheres.

The expected outcomes include a possible exploitation of CMCs in next-generation radiant tubes, providing crucial feedback for other energy-intensive applications transitioning to renewable fuel mixtures. The project highlights the potential of CMCs to significantly contribute to sustainable and efficient energy solutions.

Stay tuned for further project results visiting our website page: https://www.cem-wave.eu/progress