Revolutionizing MW-CVI process

Advancing Ceramic Matrix Composites: A Successful Collaboration between IRIS, FM, UNIPI, and IPCF-CNR, Consortium partners of the CEM WAVE Project

On the 28th of November, IRIS Techonology Solutions (IRIS) embarked on an experimental campaign at the joint laboratories of the University of Pisa (UNIPI) and the Institute for the Chemical-Physical Processes of the National Research Council (IPCF-CNR) in Pisa . This initiative, part of the larger CEM-WAVE project, aimed to revolutionize the Microwave-assisted Chemical Vapor Infiltration (MW-CVI) process, paving the way for its industrial application.

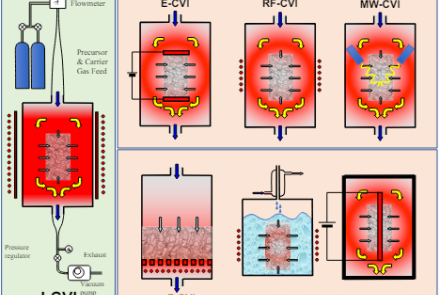

The CEM-WAVE project, a cutting-edge endeavour, focuses on harnessing the potential of microwave (MW) solid-state sources to automate the MW-CVI process. The key objective is to leverage the operating frequency tuning characteristic of MW solid-state sources to explore strategies for automating the MW heating parameters during the infiltration of Silicon Carbide (SiC) fiber reinforced SiC matrix preforms SiCf/SiC. The ultimate goal is to achieve the highest process energy efficiency while maintaining the CMC sample at the desired infiltration temperature.

Collaborators and Expertise:

The successful realization of this ambitious project hinged on the expertise and collaboration of key players. Dr. Giuseppe Annino, the leader of Work Package 2, and Dr. Roberto D’Ambrosio, both leading figures at IPCF-CNR, played pivotal roles in organizing and facilitating the experimental campaign. Their comprehensive knowledge of MW solid-state sources systems and the MW-CVI process was instrumental in guiding the research.

Researchers from IRIS, Dr. Marcelo Janvrot Vivone and Dr. Josè Luis Angulo, brought their expertise in the development of advanced monitoring tools for critical processes. Their involvement in the project was crucial for interpreting and analyzing the intricate data generated during the experimental campaign.

Collaborative Synergy:

The collaboration extended beyond IRIS and IPCF-CNR to include the University of Pisa (UNIPI) and FM (Fricke und Mallah GmbH), the entity responsible for designing and developing the MW solid-state sources system. UNIPI, with its wealth of experience in MW-CVI processing of SiC-based samples, provided valuable insights and guidance. The synergy between these entities created a powerful alliance, combining theoretical knowledge, practical experience, and technological innovation.

Achieving Milestones:

Throughout the experimental campaign, the team focused at first on automatically tracking the operating frequency shift along the MW-CVI process, as a result of the SiCf/SiC sample temperature variations and changes in its dielectric properties, followed by an andjustment of the MW transmitted power to keep itat the infiltration temperature. A dedicated control loop has been developed to apply the above-mentioned approach on all the three available MW solid-state sources tailoring the SiCf/SiC temperature profile to improve the resulting heating pattern uniformity. This meticulous approach resulted in significant advancements in the automation of the MW-CVI process, offering promising prospects for industrial applications.

Some conclusions:

The collaborative efforts of IRIS, UNIPI, and IPCF-CNR, supported by FM, have propelled the CEM-WAVE project towards achieving its objectives. The successful automation of the MW-CVI process marks a crucial milestone in the development of high-quality Ceramic Matrix Composites, opening new avenues for innovation in the field of advanced materials. As these research endeavours continue to break new ground, the collaborative spirit and expertise demonstrated by the involved institutions set a precedent for future advancements in materials science and industrial applications.